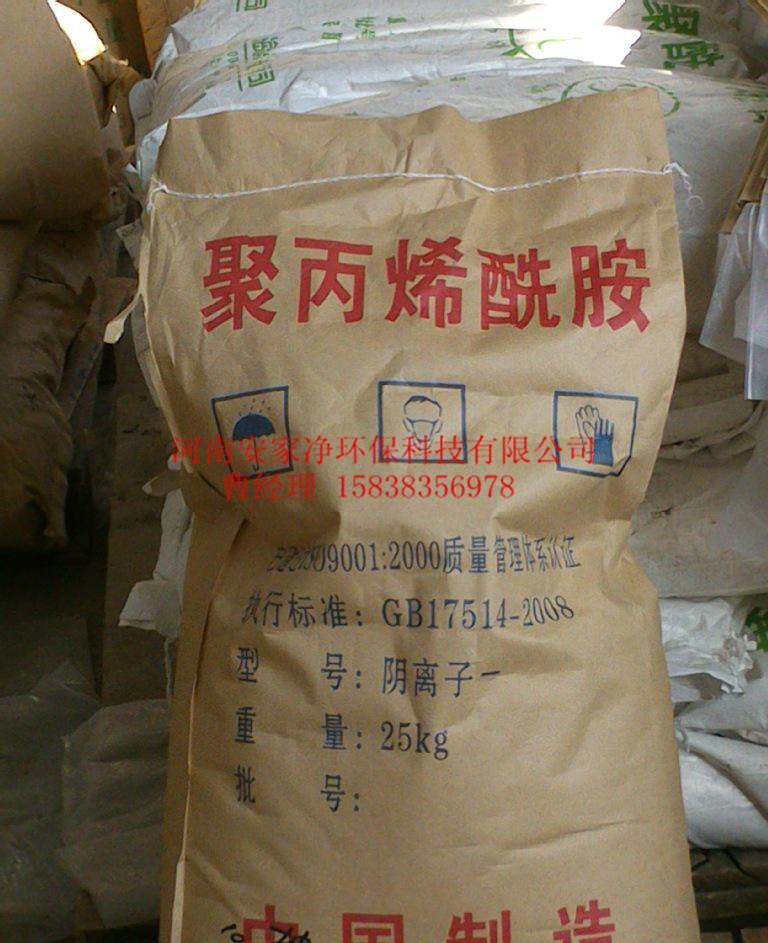

九江造纸厂食品厂污水沉淀剂阴离子聚丙烯酰胺pam高分子量增稠剂压滤脱水絮凝剂pac厂家报价

产品价格:¥4442(人民币)

商铺名称:河南安家净环保有限公司

联系人:曹经理(先生)

联系手机:

固定电话:

企业邮箱:1090222013@qq.com

联系地址:河南巩义永安路经济开发区

邮编:

联系我时,请说是在泵阀网上看到的,谢谢!

商品详情

污泥脱水沉淀剂的使用技巧 聚丙烯酰胺阴离子和阳离子的选配方法

2020年后复工开始后 各个企业陆续开始生产 很多洗沙厂 污水厂 食品厂也开始慢慢进入满负荷生产 因为长时间的停产导致很多厂里的污水存储时间太长 污泥精钢自然沉淀自然成降到底部 时间久了变得非常坚固 用污泥泵都不能抽出来 奇葩的事情比比皆是 广西金总就是一个很好的例子 2018年采购了带式压滤机 从江苏采购的 设备不能使用 使用聚丙烯酰胺处理污水效果很很好 上机就是不行 因为污

泥上不了压滤机上 沉淀后不能抽上了 污水池里搅拌扇叶太小 加进去药剂 不能重复反应 金总百感交集 试了又试 买了我家的聚丙烯酰胺阴离子 聚丙烯酰胺阳离子 聚合氯化铝都试了 药剂真好 机器不行啊 2019年金总又花钱买了个板式压滤机 还是某某品牌 广告很多 设备安装在了 高于沉淀池2米的的地方 还是出现这个问题 污泥抽不上去 不用药剂自然沉淀 时间太久用装载机吧务你挖出了 金总就是不选择药剂 压滤机滤布每个月换两次 一次1000多块 就是不用阴离道治理用的除磷剂是对城市水源水混凝除浊处理及除磷的物品。可以在对城市水源水混凝除浊处理同时,到达深度除磷意图。

从而将处理后饮用水中的磷含量降至界限值以下,不需要改动原水处理流程,不需要增设大型水处理构筑物,简便易行,经济实用,可获得显著的社会和经济效益。

河道治理用的除磷剂运用方法量投加不会造成不良影响的,毕竟铁也是微生物生长所需要的微量元素。但是如果投加量过大,则会使污泥活性收到影响,还有疑问可以到环保.通交流。

生化末端 没有影响,何况少量的铁盐能够对Phosphorus removal agent for road treatment is a kind of material for coagulation and turbidity removal of urban water source and phosphorus removal. It can reach the intent of deep dephosphorization at the same time of coagulation and turbidity removal of urban water source.

Thus, the phosphorus content in treated drinking water can be reduced to below the threshold value, without changing the original water treatment process, without adding large water treatment structures, which is simple, economical and practical, and can achieve remarkable social and economic benefits.

The amount of phosphorus removal agent used in river regulation will not cause adverse effects. After all, iron is also a trace element needed for microbial growth. However, if the dosage is too large, the sludge activity will be affected. There are still doubts about environmental protection and communication.

There is no effect on the biochemical end, let alone a small amount of iron salts.

悬浮物上漂

1、操作不当,有的是不专业的人员在实验中运用了不当手法,加入聚合氯化铝后,搅拌过急过慢都不行,初次实验,要有专业的水处理师从旁协助,这是很重要的一点。

2、加聚合硫酸铁的量没有控制好,(加药过多或过少)这种情况,最容易出现悬浮物上漂。

使用前,将本产品按一定浓度(10-30%)投入溶矾池,注入自来水搅拌使之充分水解,静置至呈红棕色液体,再兑水稀释到所需浓度投加混凝。水厂亦可配成2-5%直接投加,工业废水处理直接配 成5-10%投加。 b、投加量的确定,根据原水性质可通过生产调试或烧杯实验视矾花形成适量而定,制水厂可以原用的其它药剂量作为参考,在同等条件下本产品与固体聚合氯化铝用量大体相当,是固体硫酸铝用量的 1/3-1/4。如果原用的是液体产品,可根据相应药剂浓度计算酌定。大致按重量比1:3而定。

关于污水处理使用聚合硫酸铁上水层出现漂浮物的原因以及解决方法

污水处理1. Improper operation, some non-professional personnel in the experiment used improper techniques, adding polyaluminium chloride, stirring too fast or too slow can not, the first experiment, there must be professional

water treatment assistant, this is a very important point.

2. The amount of polyferric sulfate added is not well controlled (too much or too little dosage). In this case, suspended solids are most likely to float.

Before use, the product was put into the alum bath at a certain concentration (10-30%) and stirred with tap water to make it fully hydrolyzed. The product was put into a red-brown liquid and diluted with water until the required concentration was added and coagulated. Waterworks can also be added 2-5% directly, and industrial wastewater treatment can be added 5-10%. B. The determination of dosage depends on the proper amount of alum formed by production debugging or beaker experiment according to the nature of raw water. The other dosage used in water plant can be used as reference. Under the same conditions, the dosage of this product is approximately equal to that of solid polyaluminium chloride, which is 1/3-1/4 of that of solid aluminium sulfate. If the original liquid product is used, it can be calculated according to the concentration of the corresponding agent. It depends roughly on the weight ratio of 1:3.

Reasons and Solutions for Floating Matter in the Upper Water Layer of Polyferric Sulfate Used in Sewage Treatment

3、加聚合硫酸铁的量对了,但是废水的PH值不对,没有在相应药剂使用PH范围。适应水体PH值范围宽为4PH值范围为6-9,净化后原水的PH值与总碱度变化幅度小

4、使用净水产品的型号不对,根据污水的特点,选择适合自己污水特征的净水剂,如:聚合氯化铝、聚氯化铝、聚合氯化铝铁、氯化铝、喷雾式聚合氯化铝、白色聚合氯化铝等等,听从专业水处理师的指导意见,他们给的意见都是专业性的。

关于污水处理使用聚合硫酸铁上水层出现漂浮物的原因以及解决方法

聚合硫酸铁

5、最后一点要考虑的就是,你所使用的聚合硫酸铁,质量是否达标,聚合硫酸铁的各项指标是准。

现在市面上聚合硫酸铁的质量参差不齐,相对于质量好一些的聚合硫酸铁在使用过程中,出现悬浮物的几率会很低的,好一些的聚合硫酸铁几乎是没有水不溶物的,所以产品质量也是非常重要。微生物活性有促进作用,就是出水色度有影响

将化学除磷剂投加于生化池的后面,这样便可以完全避免水中多种物质与除磷剂发生反应,消耗药剂用量.且不会降低生化池的进水有机碳浓度,影响微生物的脱氮除磷效果。同时还可避免过多投加除磷剂,也会使残余的药剂进入生化系统中,对微生物生长造成影响。

将除磷絮凝剂投加于好氧池的出水口端,二沉池的前面投加除磷剂则可以大量减少除磷药剂的使用量,这是废水在生化处理的过程中已去除水中大部分磷,并将偏磷、有机磷转化为可通过混凝处理的正磷,大大提高除磷效果和减少除磷剂投加量,减少污泥产量、减少污泥中的磷含量。 所以,化学除磷药剂一般投加于生化后,二沉池前,节省废水除磷成本和提高达标率。?

运用时可将本产品直接投加,或先参加溶解罐,浓度为10~20%,拌和,用泵投加到反响池。本产品适用的pH值规模广,在酸性条件下运用效果尤佳,运用量约为100~1000ppm(即0.1~1公斤/吨废水),依据废水中磷酸根的含量不同其用量有所差异,详细用量一般通过试验断定。

试验时取一定量的原水,参加适量的本产品(如500ppm),将废水pH值调节至7~8,www.hnldscl.com参加少数聚丙烯酰胺PAM絮凝沉积,过滤取上清液测定磷的含量。(如需处理重金属,用上清液进行二次处理即可。)AC/PAM与除磷剂搅拌后的反应?使用时可将本产品直接投加,或先参加溶解罐,浓度为10~20%,拌和,用泵投加到反响池。本产品适用的pH值规模广,在酸性条件下使用作用尤佳,使用量约为100~1000ppm(即0.1~1公斤/吨废水),依据废水中磷酸根的含量不同其用量有所差异,具体用量一般经过试验断定。The amount of polyferric sulfate added is right, but the PH value of wastewater is not right, and there is no optimum range of PH used in the corresponding reagents. The suitable range of PH value is 4-11, and the optimum range of PH value is 6-9. After purification, the change range of PH value and total alkalinity of raw water is small.

4, the type of water purification products is not correct. According to the characteristics of sewage, choose suitable water purifying agent suitable for its own sewage characteristics, such as polyaluminum chloride, polyaluminum chloride, polyaluminum ferric chloride, aluminum chloride, spray polyaluminum chloride, white polyaluminium chloride, etc., and listen to the advice of professional water treatment division, and give their advice. They are all professional.

Reasons and Solutions for Floating Matter in the Upper Water Layer of Polyferric Sulfate Used in Sewage Treatment

Polyferric sulfate

5. The last point to consider is whether the quality of the polyferric sulfate you use meets the national standards, and whether the various indicators of the polyferric sulfate meet the national standards.

At present, the quality of polyferric sulfate is uneven in the market. Compared with the better quality of Polyferric sulfate, the probability of suspended solids will be very low. The better polyferric sulfate has almost no water insoluble solids, so the quality of products is also very important. Microbial activity has a promotive effect, that is, effluent color has an impact.

Adding chemical Dephosphorizer to the back of biochemical pond can completely avoid the reaction between various substances in water and dephosphorizer, consume the amount of reagent, and will not reduce the concentration of organic carbon in the influent of biochemical pond, affecting the effect of nitrogen and phosphorus removal by microorganisms. At the same time, it can avoid excessive dosage of phosphorus removal agents, and also make the residual agents into the biochemical system, which will affect the growth of microorganisms.

Adding phosphorus removal flocculant to the outlet of aerobic tank and phosphorus removal agent in front of secondary sedimentation tank can greatly reduce the use of phosphorus removal agent. This is because most phosphorus in wastewater has been removed in the process of biochemical treatment, and phosphorus migration and organic phosphorus are converted into positive phosphorus which can be treated by coagulation, which greatly improves the effect of phosphorus removal and improves the efficiency of phosphorus removal. Reduce the dosage of phosphorus removal agent, reduce sludge production, reduce phosphorus content in sludge. Therefore, chemical phosphorus removal agents are generally added to the biochemical process, before the secondary sedimentation tank, to save the cost of phosphorus removal from wastewater and improve the rate of reaching the standard. ?

When in use, the product can be directly added or participated in the dissolving tank, the concentration of which is 10-20%, mixed and pumped into the reaction tank. The product is suitable for a wide range of pH values, especially in acidic conditions. Its application amount is about 100-1000 ppm (i.e. 0.1-1 kg/ton wastewater). According to the different content of phosphate in wastewater, its dosage is different. The detailed dosage is generally determined by experiments.

During the experiment, a certain amount of raw water was taken and the product (such as 500 ppm) was added. The pH value of the wastewater was adjusted to 7-8. www.hnldscl.com participated in the flocculation and deposition of a few PAM. The supernatant was filtered to determine the phosphorus content. (If heavy metals need to be treated, the supernatant can be used for secondary treatment.) Reaction of AC/PAM with phosphorus removal agent after stirring? When in use, the product can be directly added or participated in the dissolving tank at the concentration of 10-20%. The product can be mixed and pumped into the reaction tank. The product is suitable for a wide range of pH values, especially in acidic conditions. Its usage is about 100-1000ppm (i.e. 0.1-1 kg/ton wastewater). According to the content of phosphate in wastewater, its dosage is different. The specific dosage is generally determined by experiments.

试验时取一定量的原水,参加适量的本产品(如500ppm),将废水pH值调理至7~8,参加少数聚丙烯酰胺PAM絮凝沉积,过滤取上清液测定磷的含量。(如需处理重金属,用上清液进行二次处理即可。) FeCl3、及 AlCl3溶液充沛混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成物,用水重复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。

该吸附剂的使用,在惯例水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时刻30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简略,质料价格低,易得安全。

PAC/PAM与除磷剂制备办法

FeCl3及 AlCl3溶液充沛混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成w物,用水重复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。

该吸附剂的使用,在惯例水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时刻30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简略,质料价格低,易得安In the experiment, a certain amount of raw water was taken and the product (e.g. 500 ppm) was participated in. The pH value of wastewater was adjusted to 7-8. A few PAM flocculating deposits were participated in. The content of phosphorus in the supernatant was determined by filtration. (If heavy metals need to be treated, the supernatant can be used for secondary treatment.) FeCl3, AlCl3 and AlCl3 solutions were mixed in NaOH solution with a molar ratio of 3:2:14; the product was filtered after mixing reaction and standing, and washed repeatedly with water until the effluent was neutral; the granular adsorbent was dried at 100-110 ~C and made into uniform size.

The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touching time 30-40 min. The adsorbent has wide application scale for phosphorus removal, excellent pollution removal efficiency, simple regeneration, low material price and easy to obtain safety.

Preparation of PAC/PAM and Phosphorus Removal Agent

FeCl3 and AlCl3 solutions were mixed in NaOH solution with a molar ratio of 3:2:14. After mixing and standing, W was filtered and washed repeatedly with water until the effluent was neutral. The granular adsorbent was dried at 100-110 C and made into uniform size.

The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touching time 30-40 min. The adsorbent is suitable for phosphorus removal on a wide scale, with excellent pollution removal efficiency, simple regeneration, low material price and easy access to safety.

FeCl3、及 AlCl3溶液充分混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成物,用水反复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。该吸附剂的使用,在常规水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时间30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简单,质料价格低,易得安全。

河道治理用的除磷剂适用规模

1、用于生活污水处理厂除磷,特别是合适中磷段污水处理;

2、合适于含外表处理工艺的工业废水;

3、用于食品厂废水;

4、用于制药、造纸、农药、化肥厂的废水处理。

5、用于废物填埋厂废物渗滤液处理。After fully mixing and homogenizing AlCl3 solution, NaOH solution was added with a molar ratio of 3:2:14; the product was filtered after mixing and standing, and washed repeatedly with water until the effluent was neutral; the granular adsorbent was dried at 100-110 (?) C and made into uniform size. The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touch time 30-40 min. The adsorbent has wide application scale for phosphorus removal, excellent pollution removal efficiency, simple regeneration, low material price and easy safety.

Application Scale of Phosphorus Removal Agents for River Regulation

1. It is used for phosphorus removal in domestic sewage treatment plants, especially for medium phosphorus section sewage treatment.

2. Suitable for industrial wastewater containing surface treatment process.

3. Wastewater from food factories;

4. Wastewater treatment in pharmaceutical, papermaking, pesticide and fertilizer plants.

5. Waste leachate treatment in waste landfill plants.

子聚丙烯酰胺 这就是经验啊 设备安装出现问题 设备白买了 洗沙专用聚丙烯酰胺因为其具有极性基因—酰胺基,于借其氢健的效果在泥沙颗粒表面吸附。

2、洗沙专用聚丙烯酰胺因其有很长的分子链,大数量级的长链在水中有无穷的吸附表面积,故絮凝效果好,能使用长链在颗粒之间架桥,构成大颗粒的絮凝体,加快沉降。

3、借助于聚丙烯酰胺的絮凝、助凝,清水处置的pH值是水处理水平的关键值。对于各种类型污水的处理和调整,pH值也是必不可少的。目前,工业废水还分为两种加工方式:酸和弱碱。 这种受水污染的废水由于其酸和碱性质而具有很强的腐蚀性,并且干扰了加工技术,这会影响水质。因此,近年来,人们经常使用物理化学方法来连续处理和调节水的pH值。它主要用化学添加剂处理。使用理化附聚氯化铝处理酸碱水污染废水:聚集氯化铝适用于酸度和碱度界限极,因此近年来工业化已被用作酸碱废水处理的调节剂PH value is the key value of water treatment level. For the treatment and adjustment of various types of wastewater, the pH value is also essential. At present, industrial wastewater is also divided into two processing methods: acid and weak alkali. The wastewater polluted by water has strong corrosiveness because of its acidity and alkalinity, and interferes with the processing technology, which will affect the water qu很多人不清楚高纯聚合氯化铝对人体健康是否有危害,以及危害性,这里可以为您提供此问题,并详细介绍高纯聚合氯化铝和身体接触是否有危害。

高纯聚合氯化铝的腐蚀性、强刺激性较强,容易对人体皮肤,粘膜产生刺激,如果长期接触的话会头晕,头疼,食欲不振,胸闷。

另外如果平时吸入大量的高纯聚氯化铝会和支气管,如果不小心吸入高纯聚氯化铝后,应该快速离开到空气清新处,如果出现呼吸困难的话必须输氧,进行人工呼吸就医。

如果误服大量高纯聚氯化铝会引起人体口腔溃烂,胃炎,胃部出血,胃粘膜坏死,一旦不小心误食后应该马上用清水漱口,或者服用牛奶或蛋清后马上就医。

ality. Therefore, in recent years, people often use physical and chemical methods to continuously treat and adjust the pH value of water saving. It is mainly treated with chemical additives. Physicochemical agglomerated polyaluminium chloride is used to treat acid-alkali wastewater. The agglomerated aluminium chloride is suitable for the extreme limit of acidity and alkalinity. Therefore, industrialization has been used as a regulator for acid-alkali wastewater treatment in recent years.

Polychloride is mainly due to the acidity and alkalinity of water, it has strong adhesion and dehydration characteristics. It has high removal rate of sewage components and is suitable for clean water, which is favored by customers. The advantages of physicochemistry and ant effect is particularly obvious. With the gradual maturity of acid-alkali wastewater treatment technology, there are many processing technologies, and now acid-alkali wastewater has also been treated.。

主要是聚氯化物由于水体的酸度和碱度,它具有很强的附着力和脱水特性。它对污水成分的去除率高,适用于洁净水,深受客户青睐。 加工酸化废水的物理化学和团聚氯化铝工艺的优势:相对酸性的水污染废水的处理需要根据酸水平测量聚集的氯化铝浓度,而碱性废水的处理相对容易因为在弱碱条件下,可以充分发挥聚氯化铝的作用,使清水中的污染物迅速凝结沉淀,不需要添加额外的助剂,酸性水污染废水需要添加中和剂以加强处理。目前,与许多处理工艺相比,使用物理化学聚氯化铝的选择相对较好,处理效果尤为明显。随着酸碱废水处理技术的逐步成熟,加工技术有很多,现在酸碱废水也已被处理掉。

泥凝过程中可能发生双电离紧缩,使颗粒集合稳定性下降,分子引力效果下颗粒结合起来,分散相的简单阴离子可以被聚合物阴离子基团所替代。

4、洗沙专用聚丙烯酰胺高分子和天然水方法所得出的分类是不一样的,假如依照离子型可分为阴、非、两性及阳离子聚丙烯酰胺,假如依照形状的话,能够分为胶体、涣散液、乳液和干粉颗粒四种形状,那么这四种形状哪一种更适合我们呢?公司给您一些主张,接下来是我们的经历所得,希望您会感兴趣。

??在平常假如我们常常运用,能够选择干粉颗粒状聚丙烯酰胺,The classification obtained by the method is different. If the ionic type can be divided into Yin, non, amphoteric and cationic polyacrylamide, if according to the shape, it can be divided into four shapes: colloid, laxity, emulsion and dry powder. Which of these four forms is more suitable for us? The company gives you some suggestions. Next is our experience. I hope you will be interested.

In general, if we often use it, we can choose dry powder granular polyacrylamide. Because of its highest solid content, dry powder polyacrylamide is generally stored in dry and cool places for more than two years, but if mixed with solution, its storage time will be limited. Generally speaking, when the concentration of solution is 0.1%, non-ionic and anionic polyacrylamide will dissolve. The stability of cationic polyacrylamide solution depends on the concentration of the solution. For example, the more concentrated the solution is, the longer the storage time of 3%-5% solution is, but the 3%-5% solution can not be directly used to treat sewage. This solution needs to be diluted before use, and the PH value of cationic polyacrylamide solution is less than 5.5. Stability, if greater than 6.0, will be due to hydrolysis and failure, water medium dispersion polyacrylamide shelf life of six months.

Therefore, polyacrylamide is still a better choice of solids, can be used with the mix, do not cause waste.

Of course, we must pay attention to the conditions and taboos of preserving polyacrylamide. Polyacrylamide is more sensitive to iron ions, calcium ions and magnesium ions than anionic polymers. In particular, iron ions are catalysts for the chemical degradation of all polyacrylamide. Therefore, in the manufacture, handling and storage of polyacrylamide solutions, we must try to avoid iron ions entering and touching the solution. The equipment should be made of plastics, stainless steel, FRP or carbon steel with surface coating resin.由于它的固含一般情况下干粉聚丙烯酰胺在干燥、阴凉的当地是寄存二年以上的,但假如配成溶液的话,它的寄存时刻就有限了,一般说,溶液浓度为0.1%的时候,非离子与阴离子聚丙烯酰胺溶液不会超过一周的时刻,阳离子聚丙烯酰胺溶液则不会超过一天,而且溶液的稳定性与溶液的浓度有关,配的浓度越浓,例如3%——5%的溶液寄存时刻越长,但3%——5%的溶液不能直接去处理污水,这种在运用前需要稀释,阳离子聚丙烯酰胺溶液PH值小于5.5的时后比较稳定,假如大于6.0的话,就会由于水解的原因而失效,水介质涣散型聚丙烯酰胺保质期为六个月。

??所以聚丙烯酰胺仍是选用固体的比较好,能够做到随配随用,不造成糟蹋。

??当然大家一定要注意保存聚丙烯酰胺各种条件和忌讳,聚丙烯酰胺对铁离子、钙离子、镁离子比阴离子聚合物质灵敏,尤其是铁离子是造成所有聚丙烯酰胺化学降解的催化剂,所以在制造、搬运与储存聚丙烯酰胺溶液的话,一定要尽量避免铁离子进入与溶液触摸设备要用塑料、不锈钢、玻璃钢或表面涂料树脂的碳钢制造。

构成中的物质和水中悬浮物,或在之前投加的水解混凝剂的离子之间发生化学相互效果,可能是络合反响。

5、聚丙烯酰胺因为分子链固定在不一样颗粒的表面上,各个固相颗粒之间构成聚合

2020年后复工开始后 各个企业陆续开始生产 很多洗沙厂 污水厂 食品厂也开始慢慢进入满负荷生产 因为长时间的停产导致很多厂里的污水存储时间太长 污泥精钢自然沉淀自然成降到底部 时间久了变得非常坚固 用污泥泵都不能抽出来 奇葩的事情比比皆是 广西金总就是一个很好的例子 2018年采购了带式压滤机 从江苏采购的 设备不能使用 使用聚丙烯酰胺处理污水效果很很好 上机就是不行 因为污

泥上不了压滤机上 沉淀后不能抽上了 污水池里搅拌扇叶太小 加进去药剂 不能重复反应 金总百感交集 试了又试 买了我家的聚丙烯酰胺阴离子 聚丙烯酰胺阳离子 聚合氯化铝都试了 药剂真好 机器不行啊 2019年金总又花钱买了个板式压滤机 还是某某品牌 广告很多 设备安装在了 高于沉淀池2米的的地方 还是出现这个问题 污泥抽不上去 不用药剂自然沉淀 时间太久用装载机吧务你挖出了 金总就是不选择药剂 压滤机滤布每个月换两次 一次1000多块 就是不用阴离道治理用的除磷剂是对城市水源水混凝除浊处理及除磷的物品。可以在对城市水源水混凝除浊处理同时,到达深度除磷意图。

从而将处理后饮用水中的磷含量降至界限值以下,不需要改动原水处理流程,不需要增设大型水处理构筑物,简便易行,经济实用,可获得显著的社会和经济效益。

河道治理用的除磷剂运用方法量投加不会造成不良影响的,毕竟铁也是微生物生长所需要的微量元素。但是如果投加量过大,则会使污泥活性收到影响,还有疑问可以到环保.通交流。

生化末端 没有影响,何况少量的铁盐能够对Phosphorus removal agent for road treatment is a kind of material for coagulation and turbidity removal of urban water source and phosphorus removal. It can reach the intent of deep dephosphorization at the same time of coagulation and turbidity removal of urban water source.

Thus, the phosphorus content in treated drinking water can be reduced to below the threshold value, without changing the original water treatment process, without adding large water treatment structures, which is simple, economical and practical, and can achieve remarkable social and economic benefits.

The amount of phosphorus removal agent used in river regulation will not cause adverse effects. After all, iron is also a trace element needed for microbial growth. However, if the dosage is too large, the sludge activity will be affected. There are still doubts about environmental protection and communication.

There is no effect on the biochemical end, let alone a small amount of iron salts.

悬浮物上漂

1、操作不当,有的是不专业的人员在实验中运用了不当手法,加入聚合氯化铝后,搅拌过急过慢都不行,初次实验,要有专业的水处理师从旁协助,这是很重要的一点。

2、加聚合硫酸铁的量没有控制好,(加药过多或过少)这种情况,最容易出现悬浮物上漂。

使用前,将本产品按一定浓度(10-30%)投入溶矾池,注入自来水搅拌使之充分水解,静置至呈红棕色液体,再兑水稀释到所需浓度投加混凝。水厂亦可配成2-5%直接投加,工业废水处理直接配 成5-10%投加。 b、投加量的确定,根据原水性质可通过生产调试或烧杯实验视矾花形成适量而定,制水厂可以原用的其它药剂量作为参考,在同等条件下本产品与固体聚合氯化铝用量大体相当,是固体硫酸铝用量的 1/3-1/4。如果原用的是液体产品,可根据相应药剂浓度计算酌定。大致按重量比1:3而定。

关于污水处理使用聚合硫酸铁上水层出现漂浮物的原因以及解决方法

污水处理1. Improper operation, some non-professional personnel in the experiment used improper techniques, adding polyaluminium chloride, stirring too fast or too slow can not, the first experiment, there must be professional

water treatment assistant, this is a very important point.

2. The amount of polyferric sulfate added is not well controlled (too much or too little dosage). In this case, suspended solids are most likely to float.

Before use, the product was put into the alum bath at a certain concentration (10-30%) and stirred with tap water to make it fully hydrolyzed. The product was put into a red-brown liquid and diluted with water until the required concentration was added and coagulated. Waterworks can also be added 2-5% directly, and industrial wastewater treatment can be added 5-10%. B. The determination of dosage depends on the proper amount of alum formed by production debugging or beaker experiment according to the nature of raw water. The other dosage used in water plant can be used as reference. Under the same conditions, the dosage of this product is approximately equal to that of solid polyaluminium chloride, which is 1/3-1/4 of that of solid aluminium sulfate. If the original liquid product is used, it can be calculated according to the concentration of the corresponding agent. It depends roughly on the weight ratio of 1:3.

Reasons and Solutions for Floating Matter in the Upper Water Layer of Polyferric Sulfate Used in Sewage Treatment

3、加聚合硫酸铁的量对了,但是废水的PH值不对,没有在相应药剂使用PH范围。适应水体PH值范围宽为4PH值范围为6-9,净化后原水的PH值与总碱度变化幅度小

4、使用净水产品的型号不对,根据污水的特点,选择适合自己污水特征的净水剂,如:聚合氯化铝、聚氯化铝、聚合氯化铝铁、氯化铝、喷雾式聚合氯化铝、白色聚合氯化铝等等,听从专业水处理师的指导意见,他们给的意见都是专业性的。

关于污水处理使用聚合硫酸铁上水层出现漂浮物的原因以及解决方法

聚合硫酸铁

5、最后一点要考虑的就是,你所使用的聚合硫酸铁,质量是否达标,聚合硫酸铁的各项指标是准。

现在市面上聚合硫酸铁的质量参差不齐,相对于质量好一些的聚合硫酸铁在使用过程中,出现悬浮物的几率会很低的,好一些的聚合硫酸铁几乎是没有水不溶物的,所以产品质量也是非常重要。微生物活性有促进作用,就是出水色度有影响

将化学除磷剂投加于生化池的后面,这样便可以完全避免水中多种物质与除磷剂发生反应,消耗药剂用量.且不会降低生化池的进水有机碳浓度,影响微生物的脱氮除磷效果。同时还可避免过多投加除磷剂,也会使残余的药剂进入生化系统中,对微生物生长造成影响。

将除磷絮凝剂投加于好氧池的出水口端,二沉池的前面投加除磷剂则可以大量减少除磷药剂的使用量,这是废水在生化处理的过程中已去除水中大部分磷,并将偏磷、有机磷转化为可通过混凝处理的正磷,大大提高除磷效果和减少除磷剂投加量,减少污泥产量、减少污泥中的磷含量。 所以,化学除磷药剂一般投加于生化后,二沉池前,节省废水除磷成本和提高达标率。?

运用时可将本产品直接投加,或先参加溶解罐,浓度为10~20%,拌和,用泵投加到反响池。本产品适用的pH值规模广,在酸性条件下运用效果尤佳,运用量约为100~1000ppm(即0.1~1公斤/吨废水),依据废水中磷酸根的含量不同其用量有所差异,详细用量一般通过试验断定。

试验时取一定量的原水,参加适量的本产品(如500ppm),将废水pH值调节至7~8,www.hnldscl.com参加少数聚丙烯酰胺PAM絮凝沉积,过滤取上清液测定磷的含量。(如需处理重金属,用上清液进行二次处理即可。)AC/PAM与除磷剂搅拌后的反应?使用时可将本产品直接投加,或先参加溶解罐,浓度为10~20%,拌和,用泵投加到反响池。本产品适用的pH值规模广,在酸性条件下使用作用尤佳,使用量约为100~1000ppm(即0.1~1公斤/吨废水),依据废水中磷酸根的含量不同其用量有所差异,具体用量一般经过试验断定。The amount of polyferric sulfate added is right, but the PH value of wastewater is not right, and there is no optimum range of PH used in the corresponding reagents. The suitable range of PH value is 4-11, and the optimum range of PH value is 6-9. After purification, the change range of PH value and total alkalinity of raw water is small.

4, the type of water purification products is not correct. According to the characteristics of sewage, choose suitable water purifying agent suitable for its own sewage characteristics, such as polyaluminum chloride, polyaluminum chloride, polyaluminum ferric chloride, aluminum chloride, spray polyaluminum chloride, white polyaluminium chloride, etc., and listen to the advice of professional water treatment division, and give their advice. They are all professional.

Reasons and Solutions for Floating Matter in the Upper Water Layer of Polyferric Sulfate Used in Sewage Treatment

Polyferric sulfate

5. The last point to consider is whether the quality of the polyferric sulfate you use meets the national standards, and whether the various indicators of the polyferric sulfate meet the national standards.

At present, the quality of polyferric sulfate is uneven in the market. Compared with the better quality of Polyferric sulfate, the probability of suspended solids will be very low. The better polyferric sulfate has almost no water insoluble solids, so the quality of products is also very important. Microbial activity has a promotive effect, that is, effluent color has an impact.

Adding chemical Dephosphorizer to the back of biochemical pond can completely avoid the reaction between various substances in water and dephosphorizer, consume the amount of reagent, and will not reduce the concentration of organic carbon in the influent of biochemical pond, affecting the effect of nitrogen and phosphorus removal by microorganisms. At the same time, it can avoid excessive dosage of phosphorus removal agents, and also make the residual agents into the biochemical system, which will affect the growth of microorganisms.

Adding phosphorus removal flocculant to the outlet of aerobic tank and phosphorus removal agent in front of secondary sedimentation tank can greatly reduce the use of phosphorus removal agent. This is because most phosphorus in wastewater has been removed in the process of biochemical treatment, and phosphorus migration and organic phosphorus are converted into positive phosphorus which can be treated by coagulation, which greatly improves the effect of phosphorus removal and improves the efficiency of phosphorus removal. Reduce the dosage of phosphorus removal agent, reduce sludge production, reduce phosphorus content in sludge. Therefore, chemical phosphorus removal agents are generally added to the biochemical process, before the secondary sedimentation tank, to save the cost of phosphorus removal from wastewater and improve the rate of reaching the standard. ?

When in use, the product can be directly added or participated in the dissolving tank, the concentration of which is 10-20%, mixed and pumped into the reaction tank. The product is suitable for a wide range of pH values, especially in acidic conditions. Its application amount is about 100-1000 ppm (i.e. 0.1-1 kg/ton wastewater). According to the different content of phosphate in wastewater, its dosage is different. The detailed dosage is generally determined by experiments.

During the experiment, a certain amount of raw water was taken and the product (such as 500 ppm) was added. The pH value of the wastewater was adjusted to 7-8. www.hnldscl.com participated in the flocculation and deposition of a few PAM. The supernatant was filtered to determine the phosphorus content. (If heavy metals need to be treated, the supernatant can be used for secondary treatment.) Reaction of AC/PAM with phosphorus removal agent after stirring? When in use, the product can be directly added or participated in the dissolving tank at the concentration of 10-20%. The product can be mixed and pumped into the reaction tank. The product is suitable for a wide range of pH values, especially in acidic conditions. Its usage is about 100-1000ppm (i.e. 0.1-1 kg/ton wastewater). According to the content of phosphate in wastewater, its dosage is different. The specific dosage is generally determined by experiments.

试验时取一定量的原水,参加适量的本产品(如500ppm),将废水pH值调理至7~8,参加少数聚丙烯酰胺PAM絮凝沉积,过滤取上清液测定磷的含量。(如需处理重金属,用上清液进行二次处理即可。) FeCl3、及 AlCl3溶液充沛混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成物,用水重复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。

该吸附剂的使用,在惯例水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时刻30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简略,质料价格低,易得安全。

PAC/PAM与除磷剂制备办法

FeCl3及 AlCl3溶液充沛混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成w物,用水重复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。

该吸附剂的使用,在惯例水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时刻30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简略,质料价格低,易得安In the experiment, a certain amount of raw water was taken and the product (e.g. 500 ppm) was participated in. The pH value of wastewater was adjusted to 7-8. A few PAM flocculating deposits were participated in. The content of phosphorus in the supernatant was determined by filtration. (If heavy metals need to be treated, the supernatant can be used for secondary treatment.) FeCl3, AlCl3 and AlCl3 solutions were mixed in NaOH solution with a molar ratio of 3:2:14; the product was filtered after mixing reaction and standing, and washed repeatedly with water until the effluent was neutral; the granular adsorbent was dried at 100-110 ~C and made into uniform size.

The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touching time 30-40 min. The adsorbent has wide application scale for phosphorus removal, excellent pollution removal efficiency, simple regeneration, low material price and easy to obtain safety.

Preparation of PAC/PAM and Phosphorus Removal Agent

FeCl3 and AlCl3 solutions were mixed in NaOH solution with a molar ratio of 3:2:14. After mixing and standing, W was filtered and washed repeatedly with water until the effluent was neutral. The granular adsorbent was dried at 100-110 C and made into uniform size.

The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touching time 30-40 min. The adsorbent is suitable for phosphorus removal on a wide scale, with excellent pollution removal efficiency, simple regeneration, low material price and easy access to safety.

FeCl3、及 AlCl3溶液充分混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成物,用水反复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。该吸附剂的使用,在常规水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时间30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简单,质料价格低,易得安全。

河道治理用的除磷剂适用规模

1、用于生活污水处理厂除磷,特别是合适中磷段污水处理;

2、合适于含外表处理工艺的工业废水;

3、用于食品厂废水;

4、用于制药、造纸、农药、化肥厂的废水处理。

5、用于废物填埋厂废物渗滤液处理。After fully mixing and homogenizing AlCl3 solution, NaOH solution was added with a molar ratio of 3:2:14; the product was filtered after mixing and standing, and washed repeatedly with water until the effluent was neutral; the granular adsorbent was dried at 100-110 (?) C and made into uniform size. The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touch time 30-40 min. The adsorbent has wide application scale for phosphorus removal, excellent pollution removal efficiency, simple regeneration, low material price and easy safety.

Application Scale of Phosphorus Removal Agents for River Regulation

1. It is used for phosphorus removal in domestic sewage treatment plants, especially for medium phosphorus section sewage treatment.

2. Suitable for industrial wastewater containing surface treatment process.

3. Wastewater from food factories;

4. Wastewater treatment in pharmaceutical, papermaking, pesticide and fertilizer plants.

5. Waste leachate treatment in waste landfill plants.

子聚丙烯酰胺 这就是经验啊 设备安装出现问题 设备白买了 洗沙专用聚丙烯酰胺因为其具有极性基因—酰胺基,于借其氢健的效果在泥沙颗粒表面吸附。

2、洗沙专用聚丙烯酰胺因其有很长的分子链,大数量级的长链在水中有无穷的吸附表面积,故絮凝效果好,能使用长链在颗粒之间架桥,构成大颗粒的絮凝体,加快沉降。

3、借助于聚丙烯酰胺的絮凝、助凝,清水处置的pH值是水处理水平的关键值。对于各种类型污水的处理和调整,pH值也是必不可少的。目前,工业废水还分为两种加工方式:酸和弱碱。 这种受水污染的废水由于其酸和碱性质而具有很强的腐蚀性,并且干扰了加工技术,这会影响水质。因此,近年来,人们经常使用物理化学方法来连续处理和调节水的pH值。它主要用化学添加剂处理。使用理化附聚氯化铝处理酸碱水污染废水:聚集氯化铝适用于酸度和碱度界限极,因此近年来工业化已被用作酸碱废水处理的调节剂PH value is the key value of water treatment level. For the treatment and adjustment of various types of wastewater, the pH value is also essential. At present, industrial wastewater is also divided into two processing methods: acid and weak alkali. The wastewater polluted by water has strong corrosiveness because of its acidity and alkalinity, and interferes with the processing technology, which will affect the water qu很多人不清楚高纯聚合氯化铝对人体健康是否有危害,以及危害性,这里可以为您提供此问题,并详细介绍高纯聚合氯化铝和身体接触是否有危害。

高纯聚合氯化铝的腐蚀性、强刺激性较强,容易对人体皮肤,粘膜产生刺激,如果长期接触的话会头晕,头疼,食欲不振,胸闷。

另外如果平时吸入大量的高纯聚氯化铝会和支气管,如果不小心吸入高纯聚氯化铝后,应该快速离开到空气清新处,如果出现呼吸困难的话必须输氧,进行人工呼吸就医。

如果误服大量高纯聚氯化铝会引起人体口腔溃烂,胃炎,胃部出血,胃粘膜坏死,一旦不小心误食后应该马上用清水漱口,或者服用牛奶或蛋清后马上就医。

ality. Therefore, in recent years, people often use physical and chemical methods to continuously treat and adjust the pH value of water saving. It is mainly treated with chemical additives. Physicochemical agglomerated polyaluminium chloride is used to treat acid-alkali wastewater. The agglomerated aluminium chloride is suitable for the extreme limit of acidity and alkalinity. Therefore, industrialization has been used as a regulator for acid-alkali wastewater treatment in recent years.

Polychloride is mainly due to the acidity and alkalinity of water, it has strong adhesion and dehydration characteristics. It has high removal rate of sewage components and is suitable for clean water, which is favored by customers. The advantages of physicochemistry and ant effect is particularly obvious. With the gradual maturity of acid-alkali wastewater treatment technology, there are many processing technologies, and now acid-alkali wastewater has also been treated.。

主要是聚氯化物由于水体的酸度和碱度,它具有很强的附着力和脱水特性。它对污水成分的去除率高,适用于洁净水,深受客户青睐。 加工酸化废水的物理化学和团聚氯化铝工艺的优势:相对酸性的水污染废水的处理需要根据酸水平测量聚集的氯化铝浓度,而碱性废水的处理相对容易因为在弱碱条件下,可以充分发挥聚氯化铝的作用,使清水中的污染物迅速凝结沉淀,不需要添加额外的助剂,酸性水污染废水需要添加中和剂以加强处理。目前,与许多处理工艺相比,使用物理化学聚氯化铝的选择相对较好,处理效果尤为明显。随着酸碱废水处理技术的逐步成熟,加工技术有很多,现在酸碱废水也已被处理掉。

泥凝过程中可能发生双电离紧缩,使颗粒集合稳定性下降,分子引力效果下颗粒结合起来,分散相的简单阴离子可以被聚合物阴离子基团所替代。

4、洗沙专用聚丙烯酰胺高分子和天然水方法所得出的分类是不一样的,假如依照离子型可分为阴、非、两性及阳离子聚丙烯酰胺,假如依照形状的话,能够分为胶体、涣散液、乳液和干粉颗粒四种形状,那么这四种形状哪一种更适合我们呢?公司给您一些主张,接下来是我们的经历所得,希望您会感兴趣。

??在平常假如我们常常运用,能够选择干粉颗粒状聚丙烯酰胺,The classification obtained by the method is different. If the ionic type can be divided into Yin, non, amphoteric and cationic polyacrylamide, if according to the shape, it can be divided into four shapes: colloid, laxity, emulsion and dry powder. Which of these four forms is more suitable for us? The company gives you some suggestions. Next is our experience. I hope you will be interested.

In general, if we often use it, we can choose dry powder granular polyacrylamide. Because of its highest solid content, dry powder polyacrylamide is generally stored in dry and cool places for more than two years, but if mixed with solution, its storage time will be limited. Generally speaking, when the concentration of solution is 0.1%, non-ionic and anionic polyacrylamide will dissolve. The stability of cationic polyacrylamide solution depends on the concentration of the solution. For example, the more concentrated the solution is, the longer the storage time of 3%-5% solution is, but the 3%-5% solution can not be directly used to treat sewage. This solution needs to be diluted before use, and the PH value of cationic polyacrylamide solution is less than 5.5. Stability, if greater than 6.0, will be due to hydrolysis and failure, water medium dispersion polyacrylamide shelf life of six months.

Therefore, polyacrylamide is still a better choice of solids, can be used with the mix, do not cause waste.

Of course, we must pay attention to the conditions and taboos of preserving polyacrylamide. Polyacrylamide is more sensitive to iron ions, calcium ions and magnesium ions than anionic polymers. In particular, iron ions are catalysts for the chemical degradation of all polyacrylamide. Therefore, in the manufacture, handling and storage of polyacrylamide solutions, we must try to avoid iron ions entering and touching the solution. The equipment should be made of plastics, stainless steel, FRP or carbon steel with surface coating resin.由于它的固含一般情况下干粉聚丙烯酰胺在干燥、阴凉的当地是寄存二年以上的,但假如配成溶液的话,它的寄存时刻就有限了,一般说,溶液浓度为0.1%的时候,非离子与阴离子聚丙烯酰胺溶液不会超过一周的时刻,阳离子聚丙烯酰胺溶液则不会超过一天,而且溶液的稳定性与溶液的浓度有关,配的浓度越浓,例如3%——5%的溶液寄存时刻越长,但3%——5%的溶液不能直接去处理污水,这种在运用前需要稀释,阳离子聚丙烯酰胺溶液PH值小于5.5的时后比较稳定,假如大于6.0的话,就会由于水解的原因而失效,水介质涣散型聚丙烯酰胺保质期为六个月。

??所以聚丙烯酰胺仍是选用固体的比较好,能够做到随配随用,不造成糟蹋。

??当然大家一定要注意保存聚丙烯酰胺各种条件和忌讳,聚丙烯酰胺对铁离子、钙离子、镁离子比阴离子聚合物质灵敏,尤其是铁离子是造成所有聚丙烯酰胺化学降解的催化剂,所以在制造、搬运与储存聚丙烯酰胺溶液的话,一定要尽量避免铁离子进入与溶液触摸设备要用塑料、不锈钢、玻璃钢或表面涂料树脂的碳钢制造。

构成中的物质和水中悬浮物,或在之前投加的水解混凝剂的离子之间发生化学相互效果,可能是络合反响。

5、聚丙烯酰胺因为分子链固定在不一样颗粒的表面上,各个固相颗粒之间构成聚合

在线询盘/留言